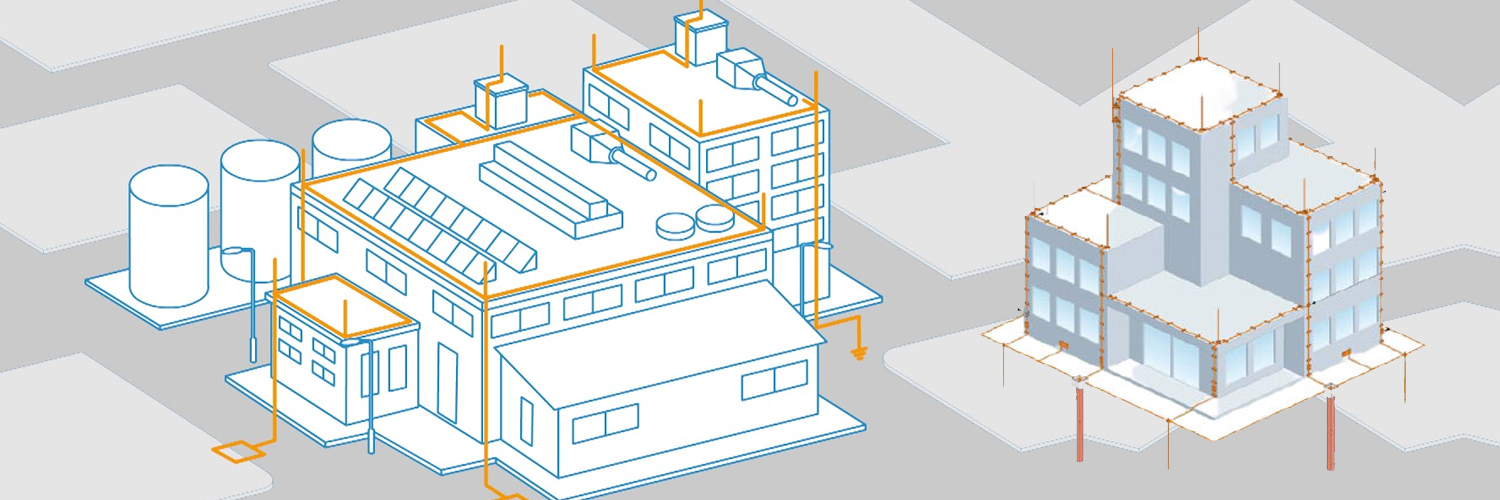

CONVENTIONAL

LIGHTNING PROTECTION SYSTEM

Protect Your Property with Conventional Surge protector

GPS India is the leading conventional lightning arresters supplier in India. ALLTEC is a leader in applying global engineered solutions that reduce risks associated with direct and indirect lightning strikes, as well as diminishing hidden effects of surge events. Trust our expertise and comprehensive product range to meet your lightning protection requirements.

We focus continuously on innovating new technology, improving solutions, refining product quality, and enhancing customer service. As Solution Providers for an Energized World, our comprehensive approach to facility protection is used to solve the world's most difficult lightning, grounding, and power quality problems. ALLTEC has the knowledge, experience, and products to provide the optimal protection solution.

All of our products are made from high-quality lightning arrester materials with strict quality assurance procedures to ensure that all of our parts will perform to specification and provide many years of worry-free service. The products includes are:

1) Air Terminal and Terminal Bases

2) Down Conductor Holder at roof terrace, and down conductor holder at wall surface And parapet,

3) Clamps, Connectors, Fasteners, and Hardware

4) Saddle Rod Brackets & Coupling Metric System

SEND ENQUIRY

STANDARDS & CODE SPECIFICATION

COMPLIANCE

ALLTEC is accredited and certified by numerous standards authorities. As an expert in the latest approved standards and code specifications for grounding and lightning protection systems, ALLTEC is a sought-after member of standards committees. When your company enlists our complete turn-key services, you ensure compliance with these organizations.

NBC - 2016

IEEE 80 & 81

UL 96A & UL 1449

NFPA 780

LPI 780

API 2003 & API 545

IEC 62305 & IEC 61643

What Is a Conventional Lightning Arrester?

A conventional lightning arrester, also known as a rod gap arrester, or traditional lightning arrester is a device that uses a series of spark gaps to conduct high-voltage surges to the ground. It consists of a metallic rod or mast connected to an earth electrode through a series of spark gaps. When a lightning bolt strikes the rod, the electrical energy is conducted through the spark gaps to the earth, thereby protecting the structure from damage.

Conventional surge protector have been in use for over a century and are still widely used today. They are typically installed on the roof of buildings or on the top of utility poles to protect them from lightning strikes.

Difference between Conventional and ESE Lightning Arresters

Conventional and ESE Lightning Arresters Comparison

| Aspect | Conventional | ESE |

|---|---|---|

| Design | Rod-like | Dome-shaped |

| Placement | On the highest point | Anywhere on the structure |

| Protection Radius | Limited range | Larger coverage area |

| Ionization | Requires a higher voltage to ionize air | Lower voltage required for ionization |

| Time Response | Higher response time | Faster response time |

| Maintenance | Regular inspection and testing | Minimal maintenance required |

| Cost | Lower initial cost | Higher initial cost |

| Compatibility | Suitable for all structures | Ideal for taller structures |

| False Tripping | More susceptible to false tripping | Less prone to false tripping |

| Installation | Requires grounding and separate conductors | Single installation without additional grounding |

Why Choose GPS India's Conventional Lightning Arresters?

If you're in the market for a conventional surge protector, GPS India is an excellent choice. Here are just a few reasons why you should consider GPS India's lightning arresters:

GPS India uses only the highest-quality materials in their lightning arresters, ensuring that they are durable and long-lasting.

GPS India's lightning arresters are rigorously tested to ensure that they meet the highest standards of performance and reliability.

GPS India has years of experience in manufacturing lightning protection equipment, making them experts in the field.

GPS India's lightning arresters are competitively priced, making them an excellent value for the money.

Benefits of Using Conventional Lightning Arresters

Using traditional surge protector has several benefits, including:

Protect your property from lightning strikes, preventing damage to your electrical systems and other infrastructure.

Improve the safety of your property by preventing electrical fires and other hazards caused by lightning strikes.

Installing lightning protection systems can lower your insurance premiums by reducing the risk of property damage from lightning strikes.

Knowing that your property is protected from lightning strikes can give you peace of mind and reduce your stress levels.

These arresters require minimal maintenance, reducing the overall cost of protecting your property from lightning damage.

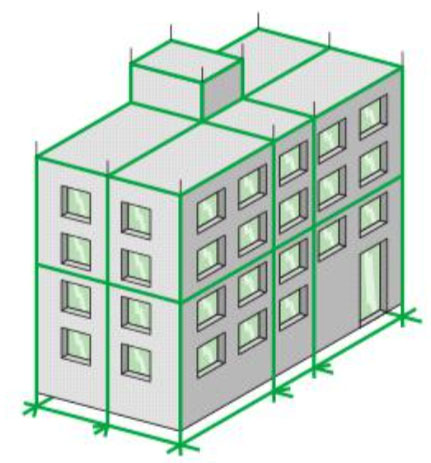

Features of Conventional Lightning Arresters

Conventional surge protector are typically composed of the following components:

Metal Rod or Mast: The arrester includes a metal rod or mast that is installed on the top of a structure. This component acts as an attractor for lightning strikes, providing a path of least resistance for the electrical energy to follow.

Down Conductor: A down conductor, usually a conductive cable or wire, is connected to the metal rod or mast. Its purpose is to conduct the electrical energy from the lightning strike downwards towards the ground.

Grounding System: The grounding system is an integral part of the conventional lightning arrester. It consists of metal rods or plates buried deep into the ground, providing a safe and effective path for the lightning-induced surge to dissipate harmlessly.

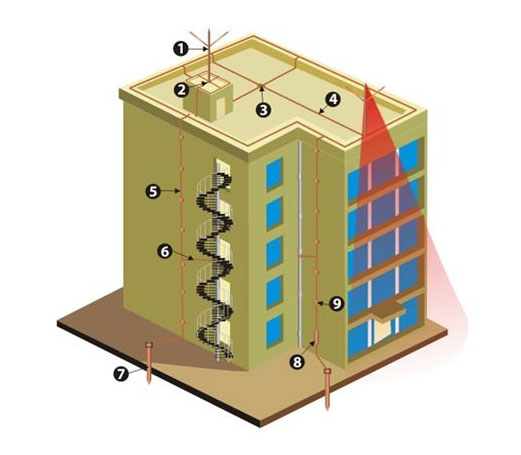

How does Conventional Lightning Arrester work?

A conventional lightning arrester, also known as a lightning rod or Franklin rod, works on the principle of providing a preferred path for lightning to follow, directing it safely to the ground and thereby protecting structures from damage. Here's a brief explanation of how a conventional lightning arrester works:

➜ A metal rod, often made of copper or aluminum, is installed at the highest point of a structure.

➜ The metal rod is connected to a conductive cable, which is, in turn, connected to a grounding system buried in the ground.

➜ The pointed tip of the rod facilitates ionization of the air around it during a thunderstorm, reducing air resistance.

➜ When lightning approaches, the ionized air provides a low-resistance path, directing the lightning to the rod.

➜ The lightning's electrical energy is conducted down the cable to the grounding system.

➜ The grounding system disperses the energy safely into the ground, preventing damage to the structure.

➜ By offering a controlled path for lightning, the arrester protects the structure, occupants, and electrical systems from potential harm.

Frequently Asked Questions

Que 1: Are conventional lightning arresters effective in protecting against all lightning strikes?

Ans: Traditional lightning arresters are designed to handle typical lightning strikes and voltage surges. However, extremely high-energy lightning strikes may pose challenges even for these arresters. It is important to assess the lightning activity and energy levels in the specific region and consult with experts to determine the appropriate level of protection.

Que 2: How often should conventional lightning arresters be replaced?

Ans: Conventional surge protector have a limited lifespan, and their components can degrade over time due to exposure to surges. It is recommended to follow the guidelines and periodically inspect and replace lightning arresters as necessary to ensure their optimal performance.

Que 3: Can conventional lightning arresters protect against other forms of electrical surges besides lightning?

Ans: Yes, Traditional surge protector are designed to handle various types of voltage surges, including those caused by switching operations, faults in the power grid, or other transient disturbances. They provide general surge protection for electrical systems beyond just lightning-related surges.

Que 4: Can I install conventional lightning arresters myself, or should I seek professional assistance?

Ans: While conventional surge protector can be installed by individuals with the necessary knowledge and expertise, it is generally recommended to involve a qualified electrician or lightning protection specialist. They can assess the specific requirements of your electrical system, ensure proper installation, and provide guidance on the overall lightning protection system design.

Que 5: Are there any alternative technologies to conventional lightning arresters?

Ans: Yes, there are alternative technologies, such as metal oxide surge arresters and gas discharge tubes, which offer different characteristics and features compared to conventional lightning arresters. These alternatives may be suitable for specific applications or situations, and it is advisable to consult with experts to determine the most appropriate solution based on your needs.

Conclusion

GPS India is a leading supplier of high-quality conventional lightning arresters. We specialize in providing reliable lightning protection solutions to safeguard your property and equipment. With our extensive experience and expertise in the industry, we offer a wide range of lightning arresters that are designed to effectively divert lightning strikes and protect against potential damages caused by electrical surges.

ALLTEC EXPERTIES:

1. Designing of Lightning protection system as per NBC-2016

2. Structure Lightning Protection.

3. Lightning Risk assessment.

4. Designing of Lightning protection system as per NBC-2016

5. Earthing design and Termination.

6. Site Surveys and analysis

7. Soil Resistivity tests and surveys.

Table as per NBC-2016 Clause 11.5.1.2: Maximum values of mesh size and protection angle corresponding to class of LPS

| Sl No | Class of LPS | Mesh Size (m) | Rolling Sphere | Protection angle with respect to height (m) |

|---|

| Radius(m) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 10m | 20m | 30m | 45m | 60m | ||||

| 1 | 5x5 | 20 | 45 | 23 | --can not be used-- | |||

| II | 10x10 | 30 | 54 | 38 | 23 | --can not be used-- | ||

| III | 15x15 | 45 | 62 | 48 | 36 | 3 | --can not be used-- | |

| IV | 20x20 | 60 | 65 | 54 | 45 | 34 | 23 |

Vertical Air Terminals

Alltec Air Terminals meet or exceed the material specifications and requirements of Underwriters Laboratories, Inc., (UL®) and the Lightning Protection Institute (LPI). Air Terminal (1148A) 1/2 - 48" UNC Threads- Standard

| Part No | Description | Weight |

|---|---|---|

| 1112A | Air Terminal, Aluminium,1/2" dia., 12" | 0.10 kg |

| 1116A | Air Terminal, Aluminium,1/2" dia., 16" | 0.14 kg |

| 1118A | Air Terminal, Aluminium,1/2" dia., 18" | 0.16 kg |

| 1124A | Air Terminal, Aluminium,1/2" dia., 24" | 0.20 kg |

| 1136A | Air Terminal, Aluminium,1/2" dia., 36" | 0.30 kg |

| 1148A | Air Terminal, Aluminium,1/2" dia., 48" | 0.40 kg |

Air Terminals Base

Used for mounting on a flat surface or against the inside of vertical walls. Can be mounted with Adhesive or fasteners. Part Number Description Weigh

| Part No | Description | Weight |

|---|---|---|

2015A |

Base,Aluminium,1/2"-13 Threaded I.D.,Flat surface, for air Terminal |

119.1g |

Cross Connector: cross connector for 8mm Aluminum conductor

| Part No | Description | Weight |

|---|---|---|

3231A |

Clamp,Aluminium,for Cross Runs, Mechanical |

101.9 g |

Universal Connector: T/L/Straight connector for 8mm Aluminum conductor

| Part No | Description | Weight |

|---|---|---|

3232A |

Clamp,Aluminium,for Straight/U Runs, Mechanical |

88.0g |

Downn Conductor: 8mm Aluminum down conductor

| Part No | Description | Weight |

|---|---|---|

4321A |

8mm Aluminum Conductor | 142g/m |

Conductor Holder: Poly plastic Conductor holder for Terrace surface

| Part No | Description | Weight |

|---|---|---|

5321A |

Conductor Holder for Terrace Flat Surface |

1.2kg |

Conductor Holder: Conductor holder for Wall parapet surface

| Part No | Description | Weight |

|---|---|---|

5322A |

Conductor Holder for wall Parapet | 50g |

Conductor Holder: Metal Conductor holder for metal roof/wall

| Part No | Description | Weight |

|---|---|---|

5323A |

Metal Conductor holder for metal roof/wall |

26.9g |

Expansion Piece: Joint for expansion and contraction of conductor

| Part No | Description | Weight |

|---|---|---|

6321A |

Aluminum, compensate the expansion and contraction of conductor |

68.5g |

Test Link Joint: Test Link Joint: Connects round and flat conductor

| Part No | Description | Weight |

|---|---|---|

7321A |

Aluminum link ,connects round and flat conductor |

87.5g |

Folding Conductor Holder: Metal Conductor holder for metal roof

| Part No | Description | Weight |

|---|---|---|

8321A |

Metal Conductor holder for metal roof/wall |

97.4g |

Aluminum Ferrule : Aluminum ferrule to connect 8 mm Al Conductor

| Part No | Description | Weight |

|---|---|---|

9321A |

Aluminum ferrule to connect 8 mm Al Conductor |

23.2g |

If You Need Any Solution. We Are Available For You !

" your Buildings, Equipments and Belongings "